What Are the Benefits of Using Open-Source CAD Software?

Commercial CAD keeps getting pricier. New subscriptions and new modules keep changing costs. However, the files are still the same, which only open properly in one program. In this hassle, it’s easy to feel boxed in.

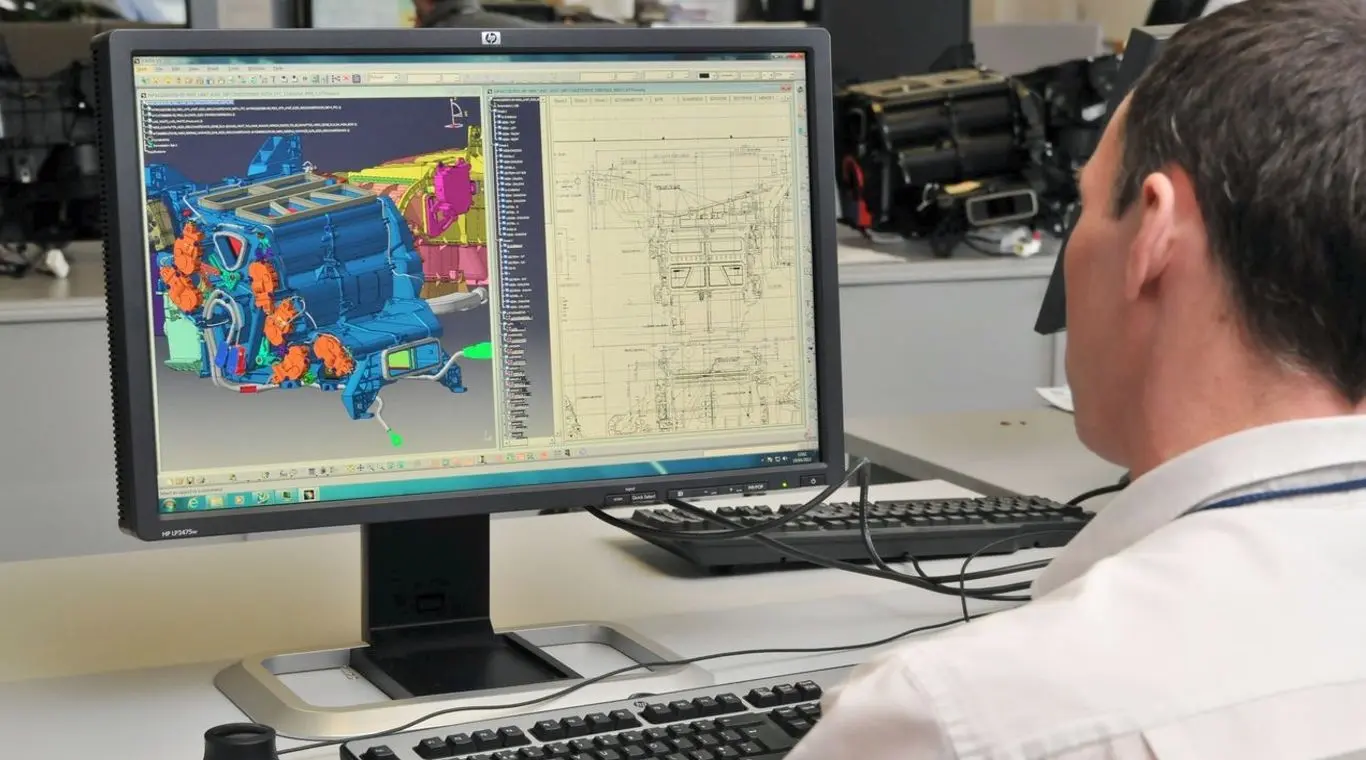

Thankfully, there’s another way! Open-source CAD tools let you run software on Windows, macOS, or Linux. Moreover, they let you tweak the code or add scripts. It also helps export to neutral formats like STEP when you need to. Teams using these tools report practical wins. That’s because of fewer license fees, simpler automation, and fewer headaches moving files between machines. A recent study even put the economic value of widely used open-source software at roughly $8.8 trillion. This is a reminder of how much code businesses lean on instead of buying from vendors.

This blog will point out the real savings, the annoyances you should expect, and which open tools suit a small shop versus a university lab. It won’t sugarcoat the rough edges. It will show concrete next steps you can try in a week.

Why this matters now

The cost of CAD software has been climbing for years. A single CAD license can now cost more than a new laptop. Some enterprise users pay $1,200 a year, others closer to $4,000, and that’s per seat, not per team. For a five-person startup, that’s a month of payroll just to keep the software running.

- While prices climb, teams are scattering. The designer who used to sit three desks away might now work from another country. Freelancers jump in and out of projects. Collaboration happens through shared drives and late-night calls instead of office whiteboards. A tool that only runs on one machine or one OS doesn’t make much sense anymore.

- Products change weekly, sometimes daily. Traditional CAD setups weren’t built for that pace. Analysts estimate the 3D CAD market will hit roughly $20 billion within the next decade. That’s 6-7% annual growth.

- Growth sounds healthy, but it also hints at pressure. So, it leads to more demand and higher licensing costs. Plus, it causes a widening gap between what big firms can afford and what smaller ones can.

- On top of that, open-source CAD tools are no longer fringe experiments; they’re becoming mature enough for serious work. The broader open-source software landscape shows that about 96% of organizations used or expanded their open-source footprint in 2024.

In short, as software costs rise, teams go remote, and manufacturing becomes more flexible and custom-driven, open-source CAD is shifting from a “nice-to-have” to a viable option for companies that need control, adaptability, and budget-friendliness now.

Here Are The Primary Benefits Of Using Open-Source CAD Software

The truth is, commercial CAD is getting expensive. Every year, prices crawl higher. If you’re small, that hurts more. The license for one designer turns into five, then ten. Suddenly, it costs more to keep the tools running than to pay the designer using them. That’s not rare anymore.

Open-source CAD came out of frustration like that. Someone needed a tool that didn’t trap them in a subscription. Something they could tinker with, fix, or expand when needed. And now, the options are actually good. Not clunky student projects but real, usable software. Let’s break down what that means in practice.

1. Cost Savings and Predictable Spend

CAD software used to be a one-time purchase. You’d buy the CD, install it, and be done. Those days are gone. Now its “annual license,” “cloud fee,” “extra module.” The bill doesn’t stop when the work does.

With open-source CAD, there’s no meter running. You download it, install it, and use it. Nobody’s watching your seat count. No pop-up says, “Renew to continue.” That kind of freedom sounds small until you run a team. Add a few more users under a commercial license, and the cost graph climbs like a rocket. Open-source doesn’t care how big you get. Five users or fifty, the price will stay the same: zero!

It’s not just the license. Upgrades are free. You update when you want. You don’t lose access because some vendor decided your version is “too old.” The team learns one tool and sticks with it for years without paying to relearn another.

Engineers also like that open-source tools use standard formats. You’ll see STEP, DXF, and STL as the usual suspects. People switch between them easily. You can hire someone who’s never touched your specific setup, and they’ll still get it.

Typical spots where the savings show:

- No renewal fees.

- No forced upgrade cycles.

- You can install it anywhere. Home, work, or laptop, it doesn’t matter.

- You spend the leftover budget on things that actually build something.

It’s not about “free software” in the gimmicky sense. It’s about getting control over what you pay for. Predictable costs are rare in tech. This is one of the few times you actually get them.

2. Freedom from Vendor Lock-In and Better Interoperability

Ever tried to open an old project after switching CAD systems? It’s painful. Some files just refuse to load. Constraints vanish. Half your assemblies break. You can almost feel the hours slipping away. That’s lock-in and the invisible leash hidden in the fine print.

Open-source CAD doesn’t play that game. It speaks open languages. STEP. IGES. OBJ. DXF. Those are formats everyone understands. You can take a part from FreeCAD, open it in something else, tweak it, bring it back, and it’ll still behave. That’s underrated until you’re knee-deep in a migration project and realize half your models won’t open.

This kind of flexibility matters even more for distributed teams. Someone’s on macOS, someone’s on Linux, someone’s still using a Windows tower from 2014. Doesn’t matter. It runs on all of them. And when a client insists on using another platform, you can just export and move on instead of arguing about compatibility.

Here’s how it quietly pays off:

- You can plug it into CAM tools to generate paths without extra software.

- You can feed models straight into 3D printing

- You can move assemblies into PLM systems with no weird conversion steps.

And if one day you decide to drop the tool altogether, you don’t lose your work. You carry your files somewhere else and keep designing. That’s the difference between renting and owning. Proprietary tools rent your workflow to you; open-source lets you keep it.

3. Customization and Extensibility

The fun part about open-source CAD? You can mess with it. Really mess with it. Change things. Add buttons. Write scripts. There’s a Python console sitting there, waiting. You don’t need permission to automate your own workflow.

Let’s say you make the same kind of part every week. These can include:

- Custom brackets

- Enclosures

- Spacers

Instead of redrawing them each time, you can write a small script that does the boring stuff related to holes, labels, thickness, all of it. You punch in new numbers, and it updates instantly. A couple of lines of code, and suddenly you’re saving hours.

Because the structure’s open, it connects to almost anything:

- Link to FEA or CFD solvers if you want an analysis.

- Build a bridge to manufacturing scripts or BOM generators.

- Push model data into a version control system like Git.

People build plugins all the time. You’ll find add-ons for architecture, robotics, machining, even CNC path generation. You download what you need, ignore what you don’t. Try doing that with a closed system and you’ll hit a wall of license terms before the first line of code.

And if something bugs you, you can actually fix it. Change the script. Edit the macro. You’re not waiting for a faceless support line to maybe pass your ticket up the ladder next month. It’s your tool. You get to shape it the way you work, not the other way around.

4. Community Support, Transparency, and Rapid Innovation

Here’s what surprises people the most: the help actually works. The forums, the chat rooms, the Reddit threads. Real users answering questions. Not copy-pasted scripts from tech support.

Ask something on the FreeCAD forum and you’ll often get a reply in hours. Sometimes from the same person who wrote the feature you’re asking about. Bugs don’t hide for years in a corporate queue. Someone sees it, fixes it, and uploads the patch. Done.

You can even watch it happen. The code, the commits, the pull requests. You can see why something broke instead of guessing. There’s a strange kind of comfort in that transparency. You stop worrying about what the software’s doing behind the scenes because you can literally look.

Security-wise, it’s also easier to trust. There’s no hidden telemetry. No cloud check-ins you didn’t agree to. For fields that care about confidentiality (medical, defense, industrial design) that openness matters.

Innovation moves differently, too. There’s no annual marketing cycle. Updates just roll in when they’re ready. Someone needs a feature, someone else writes it, everyone benefits. The pace can be unpredictable, but in a good way, real users drive it.

It’s not perfect. Some discussions go in circles. Some features stall. But it’s honest progress, not a roadmap written by accountants.

5. Lower Barriers to Learning and Recruitment

Ask a group of young engineers which CAD they used first. Most won’t say SolidWorks or Inventor. They’ll say FreeCAD, or LibreCAD, or something they downloaded for free in college. That early exposure makes a difference.

It means a new hire might already know the basics (sketching, constraints, assemblies) before you ever hand them a project. You don’t have to burn weeks on formal training. They open it up, start designing, and figure out the rest.

That learning pattern keeps growing. Universities like open-source because it’s accessible. Students can install it on a regular laptop instead of begging for lab time. They can dig into how things work instead of memorizing button locations. When they break something, they learn by fixing it. That’s how real engineers learn anyway.

For companies, that translates to:

- Faster onboarding.

- Lower training budgets.

- A larger pool of people who already know the environment.

And it doesn’t stop at students. Makers, freelancers, small workshops, they all use these tools. When you hire from that crowd, you’re hiring people who’ve already been building things their own way for years. That kind of independence fits open-source perfectly.

Contact Our Team To Get Exceptional CAD Drafting

6. Flexibility for Niche and Research Use

Some projects just don’t fit standard software molds. Maybe it’s academic research, maybe robotics, maybe something odd like prosthetic design or art installations. Commercial CAD tools usually aren’t built for that. You hit the limits fast.

Open-source CAD doesn’t mind weird projects. You can bend it however you need. Write custom scripts. Add experimental solvers. Build interfaces that talk to other research tools.

I’ve seen university labs use FreeCAD to model robot joints and feed them straight into physics simulations. I’ve seen architects build lightweight BIM setups with open plugins. Manufacturing teams link CAD data directly to machine sensors so parts update automatically when tolerances change.

Examples show up everywhere:

- BIM extensions for architecture.

- FEA/CFD add-ons for analysis work.

- Generative scripts that evolve designs algorithmically.

When a commercial vendor ignores your niche, open-source doesn’t. You just build what you need, or someone already has. And if it breaks, you fix it. That loop (use, adjust, share) keeps the ecosystem alive.

The biggest win isn’t just flexibility; it’s control. You don’t wait for a release note to say, “Now supports your workflow.” You already support it because you built it.

Putting It Together

Open-source CAD isn’t shiny or perfectly smooth. You’ll hit rough spots. Some things take longer to figure out. But it grows with you. It doesn’t disappear because a company merged or decided your version isn’t profitable. It’s not a rented space. It’s something you own.

If you add up the pieces like zero licenses, open formats, endless tinkering, and a helpful crowd of users, it starts to look less like a cheaper substitute and more like a quiet rebellion against how software usually works.

That’s the real value. Not the price tag. It’s the freedom to keep building on your own terms.

Tradeoffs & when proprietary still makes sense

Let’s be honest, open-source CAD isn’t perfect. It covers a lot of ground, but not everything. Sometimes, the commercial stuff really does earn its keep. You notice it when you’re deep in a project and something feels slower, or rougher around the edges.

For starters, the polish. Commercial CAD tools have entire design teams tweaking icons, smoothing menus, and making sure every click feels intentional. Open-source software doesn’t always have that. Some interfaces feel dated, some workflows take a few extra steps. You can live with it, but if you’re used to something like SolidWorks or Creo, it’ll feel different. Maybe not worse, just less “guided.”

Support is another one. With open-source, the “help desk” is a mix of forums, GitHub threads, and other users. It works surprisingly well most of the time, but there’s no guaranteed fix-by-Friday. If your project depends on uptime or if you’re running a production line that can’t stall, that lack of an SLA (service-level agreement) can sting. You can hire consultants, sure, but it’s not the same as calling a vendor and getting an engineer on the phone in ten minutes.

Then there’s the deep tech stuff, the high-end modules. Advanced simulation, parametric surface modeling, CFD integration, CAM with five-axis machining, the kind of features that big aerospace or automotive companies rely on. Those tend to live in the proprietary world. Open-source tools can get close, but not all the way. Some modules exist, but they might be experimental or slower to update.

So how do you decide?

Don’t overthink it. Make a simple table. Three columns: cost, feature needs, support risk. Fill them out honestly.

- If cost is killing you and your needs are mostly modeling, open-source wins.

- If you need top-tier simulation or a support contract, you can call at 2 a.m., proprietary wins.

- If you’re in the middle, maybe do both: use open-source for design and commercial tools for final validation or manufacturing.

It’s not a religion. It’s just tools. You can mix and match. Some of the smartest teams do exactly that: FreeCAD for fast concepting, SolidWorks or Siemens NX for the polished, production-ready stuff.

Side-by-side comparison table of Open Source CAD Software

A compact table for quick scanning.

| Tool (example) | Best for | Strengths | Limitations | Suggested audience |

| FreeCAD | 3D parametric modeling, BIM, FEA basics | Parametric, Python scripting, modular, many file formats. | UI learning curve; maturity varies by workbench. | SMB engineers, startups, educators. |

| LibreCAD | 2D drafting | Lightweight, DXF/DWG-friendly, easy for drafters. | No native 3D support. | Drafting teams, students. |

| OpenSCAD | Programmatic/modeling for precise parts | Code-driven parametric designs; great for repeatable parts. | Not WYSIWYG; needs coding skills. | Makers, parametric parts for 3D printing. |

| BRL-CAD | Engineering/legacy solid modeling | Mature, accurate CSG modeling, used in defense historically. | Steeper learning curve; niche. | Specialized engineering teams. |

Tips, Best Practices & Warnings

If you’re switching to open-source CAD, or even just trying it on the side, a few habits can save you from future headaches. Some of this stuff sounds boring until it breaks, then you wish you’d set it up earlier.

Quick Tips

● Pick one main file format and stick with it

Everyone’s tempted to mix and match, FreeCAD files here, STL exports there, maybe a stray DXF in someone’s Dropbox. That chaos adds up. Keep one canonical format for solids, like STEP. It’s boring advice, but when you reopen a project six months later, you’ll thank yourself.

● Version control isn’t just for code

CAD files change a lot. A missed update can ruin a whole assembly. Use Git LFS or a CAD-aware PDM system. Even a simple folder structure with dated saves is better than nothing. If you’ve ever had two engineers arguing over which “final_final.stp” file is real, you know why this matters.

● The community is your helpdesk

Don’t dig alone. There are plugin directories, subforums, Discord servers, and people who’ve already solved your exact problem. You’ll find scripts that automate dull stuff, and others that fix bugs before you even report them. It’s one of the quiet superpowers of open-source tools: you’re never the only one stuck.

Warnings

● Compliance isn’t optional in regulated work

If you’re in aerospace, medical, or defense, check your compliance needs first. Some projects legally require certified software chains. Open-source tools often don’t come with that stamp. They’re great for concepting or R&D, but final production might need certified tools.

● Test before you commit

Don’t flip the switch on your whole team overnight. Run a few parts through your manufacturing CAM pipeline first. Make sure file exports, tolerances, and toolpaths still line up. Interoperability can trip you up in ways you won’t see until it’s too late.

● Know who can fix things when they break

Open-source is freedom, but freedom comes with responsibility. If uptime matters (production floors, client deadlines) make sure someone in-house knows how to troubleshoot, or pay for outside support. Forums are fast, but not always instant.

FAQs

Is open-source CAD free for commercial use?

Yes, mostly. The majority of open-source CAD programs are licensed under permissive terms like LGPL or GPL, which means you can use them in a business setting without paying. The only real caveat is this: read the license. Some require that if you modify the source code itself and distribute it, you share those changes. For normal use, it’s fine.

Can open-source CAD handle manufacturing workflows?

Often, yes. Many tools export standard file formats like STEP or STL, which most CAM and PLM systems understand. Still, test before you bet the factory on it. Try running a small part through your workflow first. You’ll find the weak spots fast.

Which tools are best for 2D drafting vs. 3D parametric modeling?

It depends what you’re building.

- For 2D work, LibreCAD and QCAD are straightforward, light, and good for drawings or laser-cut layouts.

- For 3D parametric modeling, FreeCAD and OpenSCAD lead the pack. Blender can handle mesh work or concept modeling, though it’s not strictly CAD.

How do I get support for open-source CAD?

Mostly through the community. Forums, GitHub, Reddit, and Discord channels are active, especially for FreeCAD. If you want something closer to enterprise support, there are consultants and small firms who specialize in training and setup. It’s less “call a hotline,” more “talk to someone who actually wrote part of the code.”

Will switching break my existing CAD files?

Sometimes, yes. Proprietary file formats don’t always convert perfectly. You can usually move solid geometry through STEP or IGES, but constraints or assembly relationships might not carry over. The smart way: pick a few test assemblies, export them, reimport, and see what fails. It’s better to find out on a mock-up than mid-project.

Can I automate CAD tasks?

Absolutely. FreeCAD, in particular, has a built-in Python console. You can write scripts to batch-generate parts, update dimensions, or export drawings automatically. It’s one of the reasons developers and mechanical engineers love it, you can turn tedious steps into repeatable, shareable tools.

Conclusion

Open-source CAD isn’t a cheap copy of something else; it’s a different mindset. You save money, yes, but you also gain control: over updates, over workflows, over how your tools fit into your business. The communities move fast, plugins grow daily, and if something’s missing, someone’s already building it.

That said, not every team should drop their paid tools tomorrow. Some industries still need certifications, advanced simulations, or support guarantees. The trick is balance, knowing where open-source fits and where it doesn’t.

If you’re thinking about switching, test it. Start small. We help teams do exactly that by planning migrations, setting up hybrid environments, and training staff so the shift actually sticks. Reach out if you want to make the move without losing momentum.