How CAD Design Impacts Building Material Efficiency and Waste Reduction

Some days it feels like construction is just chaos with a hard hat. The clock’s always ticking, someone’s short on workers, and materials cost more every month. On top of that, everyone’s talking about sustainability. Sounds great, right?

But here’s the thing nobody likes to admit: about a third of all waste in the world comes from construction and demolition. Let that sink in!

Some reports even say 30% of the stuff delivered to a job site ends up in the dumpster. That’s money, time, and energy, all gone.

Now, CAD doesn’t sound exciting, but it’s kind of the quiet hero here. It’s not just for drawing walls and windows anymore. It’s for getting things right before anyone lifts a hammer. CAD tells you what fits and what doesn’t. It catches the tiny mistakes that become big, expensive problems later. A good CAD file can stop someone from cutting steel twice or tossing a misfit railing into the scrap pile. It’s like having an extra brain that doesn’t forget measurements or second-guess slope angles. Less guessing, less waste, fewer swears on the job site.

In this piece, we’ll look at how CAD design actually trims down material waste, saves cash, and helps construction projects stop bleeding resources.

Why CAD is the Foundation of Efficient Construction

CAD drawings aren’t just blue lines on a screen anymore. They’ve become the instruction manual for everything that happens after the design phase.

A solid CAD model tells you exactly how much stuff you need, where it goes, and how it’s supposed to fit together. And we are not talking about roughly, but exactly!

That’s what stops people from ordering “a few extras, just in case,” which is usually how you end up with a dumpster full of expensive scrap.

How CAD Cuts Through the Guesswork

When you rely on hand-drawn layouts or vague dimensions, someone on-site is going to make a call with a tape measure and a shrug. That’s how errors creep in.

CAD flips that script. It’s brutally precise and spells out:

- Material quantities: down to bolts, panels, and welds.

- Placement details: so the left column doesn’t mysteriously drift 2 inches from where it should be.

- Component interactions: how steel meets concrete, how insulation tucks behind cladding, how railings align with stairs.

Don’t Take Our Word For It: See The Numbers!

Here’s what efficient CAD use can influence on a typical mid-sized commercial project

| Area | Average Reduction | Notes |

| Material waste | 20–30% | Comes from better ordering accuracy and prefabrication alignment |

| Rework hours | 25% | Most rework happens from design mismatches caught late |

| Procurement costs | 10–15% | Fewer over-orders and last-minute shipments |

| Project delays | Up to 12% faster completion | Precision means fewer “do-over” moments |

Based on 2024 data from Autodesk and McKinsey research

These numbers vary, sure, but even the low end is huge when steel, concrete, and labor all cost more every month.

Here Are The Trades Where It Really Shows Up

It’s not just about the drawings. The impact hits everywhere:

- Steel fabrication: No more cutting beams twice because of a missing dimension.

- Concrete layout: Rebar, formwork, and anchor bolts all align because CAD already planned it.

- MEP systems: Electrical, HVAC, and plumbing don’t fight for the same space once coordination models are in place.

Even the small stuff (like where to mount handrails or align brackets) becomes smoother. The more that’s worked out before anyone picks up a tool, the less that ends up in a landfill later.

At the end of the day, that’s what efficient construction actually looks like. It’s just less guessing, fewer redos, and a site that runs like someone planned it that way on purpose.

Streamlines Steel Usage

Steel is one of the most ubiquitous construction materials. Load-bearing frames and weather-resistant facades can be found at all levels of the structure.

Unfortunately, it is also one of the most expensive materials. It is heavy, causing significant investment in transportation and machinery. It is also highly susceptible to fluctuating market conditions.

The cost of miscutting steel is unforgiving. So, both structural and architectural steel components must be fabricated with the utmost precision.

Tools such as SolidWorks and Revit make this entirely possible. Steel components can be created down to the very bolt hole. This guarantees that 3D drawings align perfectly with actual field conditions.

CAD capabilities are largely responsible for the proliferation of prefabricated steel processes. Steel manufacturers can use detailed CAD drawings to pre-cut all structural columns and bracings off-site. Since the models include accurate connection details and slab elevations, no modifications are necessary at the construction site. This saves days of install time and eliminates several tons of steel waste for each project.

Railing Precision

A deceptively complex element of building design: commercial railings. They aren’t just screwed onto the wall once the structure is complete. A few intricacies specific to railings include:

- Exact mounting dimensions

- ADA compliance

- Tight tolerances

- Clear sight lines

It all adds up to making CAD accuracy non-negotiable.

Among the most common sources of waste in railing installations are poor field measurements and unclear design intent. This often occurs because designers try to guess bracket spacing or cut posts on-site. It often results in miscutting the railing material and/or creating entire railing sections that don’t fit and get discarded.

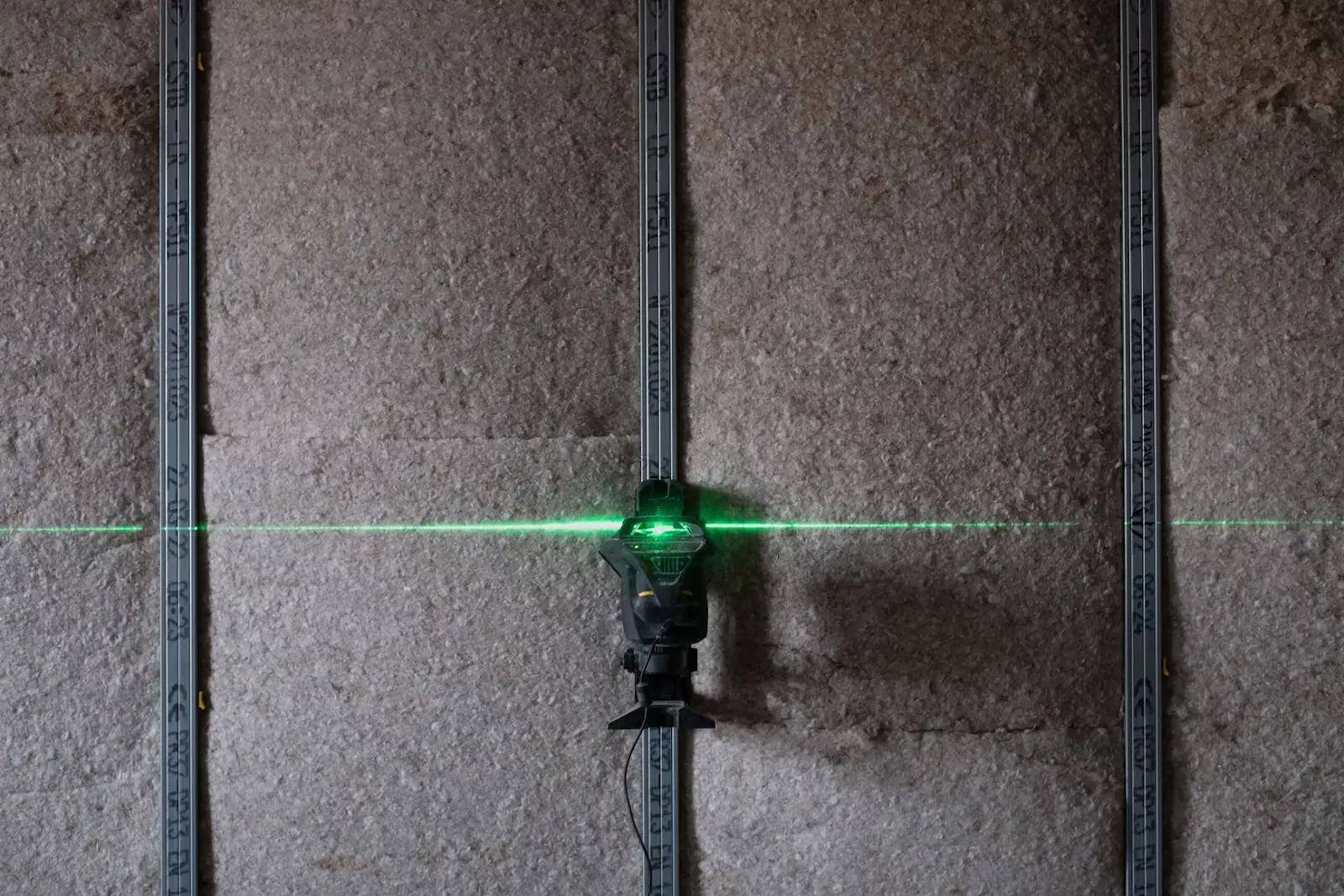

Via CAD, it is possible to deliver detailed drawings that include precise anchor point locations. CAD can offer detailed post heights adjusted for slopes. It can recommend cut lengths down to the millimeter. This helps railing manufacturers pre-assemble sections in the factory. It drastically reduces field waste. It streamlines installation time.

High-performance building envelopes are no longer optional. The insulation has to fit right. Gaps and Bridges are not acceptable. If the insulation doesn’t do its job, the whole wall system squeaks and your energy bills will let you know.

But what if the insulation order is incorrect? That’s when waste creeps in.

- Thermal bridging happens. Heat flows through unintended paths.

- Scrap materials build up. Off-cuts fill dumpsters instead of being used.

- More transport, more manufacturing are needed for replacements. So, it leads to more embodied carbon.

- The installer spends time measuring, adjusting, improvising. That time costs money and creates risk for mistakes.

On projects that rely heavily on on-site measuring and adjustment, waste percentages from insulation trimming and misfits can run high. By contrast, when models are used early, some builders report up to 20% savings in waste from insulation alone.

Here are some more waste numbers worth knowing:

| Item | Typical Waste Without Tight Modeling | With Precise CAD Modeling |

| Insulation off-cut / trimming | High (varies by site) | Up to 20% lower waste reported |

| Re-work for mis-fit panels | Several hours per section | Minimal, because model catches interface clashes |

| Ordering excess insulation “just in case” | Often 10-15% extra | Much lower, closer to actual usage |

| Installer confusion / onsite adjustment | Frequent | Rare when model delivers clarity |

Here’s What Good CAD Modeling Does for Insulation

- It maps out every interface: where the insulation meets the cladding, where fasteners go, and where different thicknesses change.

- It enables section views that show installers exactly “this panel here is 3-inches, that one over the slope is 4-inches” and everything is colour-coded so crews aren’t guessing.

- It changes ordering practices: instead of “we need 10% extra just in case,” you order almost exact quantities.

- It supports factory or off-site prefabrication of wall panels with insulation already installed or cut to fit, which cuts waste and on-site time.

CAD’s Role in Greener Construction

When people talk about “green buildings,” the focus usually jumps straight to solar panels, recycled steel, or fancy energy systems. That’s all great, but the truth is simpler. You can’t call a project sustainable if it wastes half its materials before the ribbon cutting.

That’s where CAD sneaks in. Not flashy or loud, just quietly cutting down waste one digital drawing at a time.

Less Guessing, Less Carbon

Every mistake on-site has a carbon price tag. Mis-measured rebar? That’s steel mined, smelted, and shipped for nothing. Was a wall built wrong? That’s concrete poured twice. That means double the cement and double the emissions.

Here’s how CAD indirectly tackles the big environmental stuff:

- Fewer raw materials mined or quarried: because the quantities are calculated accurately the first time.

- Lower processing energy: less milling, smelting, or cutting scrap.

- Reduced transport emissions: fewer replacement orders and emergency deliveries.

- Smaller landfill loads: because the offcuts and bad batches just don’t happen as often.

It’s not glamorous, but this quiet precision can shave 10–25% off a project’s embodied carbon, depending on the material mix and how closely the design is followed.

| Impact Area | Typical Reduction Using CAD | Why It Happens |

| Embodied carbon in structure | 10–25% | Fewer wasted materials and duplicate fabrication |

| Site fuel use | 8–15% | Less hauling, fewer redo trips |

| Landfill contribution | 20–30% | Precise prefabrication and cutting plans |

| Overall project emissions | 5–10% | Combined benefit of fewer deliveries and less rework |

Numbers vary, of course. A sloppy team with perfect software still makes a mess. But a sharp crew using accurate models can make a real dent in a building’s footprint.

A Tool That Actually Pays for Itself

It’s tempting to see sustainability as an expense, but CAD makes it feel more like common sense. It saves money and materials.

At the end of the day, greener construction isn’t about slogans. It’s about precision that keeps waste out of the dumpster and emissions out of the air. And most of that starts, quietly, on a designer’s screen.

The Final Takeaway: CAD Precision Is the New Standard for Material Efficiency

At this point, it’s pretty clear that CAD isn’t just for people who like clean 3D renderings or tidy drawings. It’s the difference between a job that runs smoothly and one that bleeds money from waste bins.

Every time a beam fits perfectly or an insulation panel slides into place without trimming, that’s CAD doing its job. It saves material, time, and a few headaches. It doesn’t scream for attention, but its fingerprints are all over the projects that finish on budget and don’t fill the landfill halfway through construction.

If you want to see how this actually works in practice, get your hands on real CAD workflows that cut waste and make the build process cleaner. You can check out CAD Drafter.

If you’re ready to turn your designs into something that fits the first time, reach out. Let’s build smarter, waste less, and leave fewer regrets behind.