Parametric & Algorithmic Drafting in Construction: When and How to Use It

The construction world is under serious pressure right now, budgets are tighter, timelines are shorter, and clients expect more from technology than ever before. Yet while about 74% of US contractors now report using Building Information Modeling (BIM) in some capacity, many firms still struggle to turn it into real productivity gains.

Enter parametric and algorithmic drafting: when done right, these methods transform how teams design, coordinate and build. They don’t just replace manual CAD work; they reshape workflows so drawings update automatically, fabrication can proceed faster, and errors get caught much earlier.

In this article, you’ll get a clear explanation of what parametric and algorithmic drafting really mean, the tools that industry teams are using (think automation scripts, family tools, mass-custom modules), and how to decide when the investment is worth it on your project. You’ll read about real-world return on investment (ROI) through faster delivery, fewer clashes, better prefab coordination, plus the steps a US-based CAD drafting partner (that’s us, CAD Drafter) can take to help you win.

By the end, you’ll know how to spot the right opportunities, avoid common pitfalls, pick the right platform, and make parametric drafting a driver of business value rather than just a trendy buzzword.

What are Parametric and Algorithmic Drafting?

Parametric and algorithmic drafting are cousins, not rivals, because both replace repetitive manual drafting with rule-driven logic, but they do it at different depths.

Here’s a complete breakdown of both types of drafting:

Parametric drafting explained

Parametric drafting is about relationships. You build an object once as a family (or template) and give it parameters, length, height, material, vent size, mullion offset, whatever matters. Change a parameter and every linked dimension, tag, or schedule that depends on it updates automatically. Think of a Revit window family: set width, height, and ventilation-percentage parameters, and the family’s geometry, frame cut, and tag values shift to match. That saves hours of manual edits and keeps documentation synchronized with design changes. Parametric families are the simplest, most durable way to capture “design intent” inside a model.

Key behaviors you can expect from parametric families:

- Defined input controls (numeric, yes/no, types)

- Embedded rules that maintain geometry and clearances

- Downstream data that feeds schedules, tags, and takeoffs.

Algorithmic/computational drafting explained

Algorithmic drafting uses code or visual scripts to produce geometry, assemblies, or documentation. Instead of a handful of sliders, you create logic: loops, conditionals, data trees, fitness rules. A common pattern is an adaptive grid for a façade that reads site inputs (column positions, sun angles, desired panel sizes) and then iteratively adjusts panel boundaries, edge conditions, and attachment points until constraints are met. Tools such as Grasshopper and Dynamo let teams run that logic visually. Behind the nodes sits traditional algorithmic thinking and stepwise instructions that a computer follows. This is where you start automating decisions that would otherwise require many manual passes.

Real-world algorithmic uses include:

- Adaptive panelization for complex facades

- Automated routing rules for MEP prefabrication

- Parameter sweeps for daylight or energy optimization.

How They Overlap: The Practical Spectrum

These techniques form a spectrum rather than separate lanes. At the left: parametric families that enforce consistent behavior (fast, predictable, low risk). In the middle: algorithmic scripts that assemble and refine many families or elements (more flexible, requires scripting discipline). At the extreme right: generative systems that produce many design variants and rank them by objectives (cost, performance, fabrication ease).

In practice, a project often mixes all three: parametric families authored in Revit, algorithmic layout in Grasshopper or Dynamo, and a lightweight generative run for a handful of facade scenarios. The interplay is what makes modern construction workflows powerful, and what requires careful governance so models stay readable and usable.

Why construction teams are adopting parametric and algorithmic drafting

The short answer: pressure. Budgets are tight, schedules are compressed, and owners want predictable outcomes. But there’s a longer, practical reason: the industry already has the digital backbone (BIM) in place, and teams are looking for ways to turn that data into lower cost, less waste, and faster delivery.

Below are the main drivers and how these methods translate to measurable gains on real projects.

Faster iteration and design-to-document workflows

When a change arrives (and it always does), parametric families and scripted updates stop the scramble. Change one parameter and related drawings, tags, schedules, and cut lists update automatically. That reduces manual rework and shortens the loop between design decision and construction documentation.

Teams using automation report faster turnarounds on revisions and fewer version mismatches between model and shop drawings. In practice this means fewer RFIs that exist purely because a family wasn’t updated, and fewer late-night redraws to catch up with last-minute design changes. These gains stack repeated changes on a large project, compounding the time saved.

Improved coordination with BIM

Algorithmic rules and parametric constraints make coordination less ad hoc. Scripts can run clash checks, apply company standards, and flag nonconforming geometry automatically. That’s why firms integrating parametric checks into their BIM pipelines find clashes earlier (when fixes are cheap) not during fabrication or on site.

For MEP particularly, BIM-linked prefabrication and rule-based routing have been tied to productivity improvements; studies show MEP productivity gains from BIM integration in the range of about 5–25%, depending on scope and maturity. Those are real labor savings and fewer surprises for subs.

Better design-for-fabrication & prefabrication

Factory production wants predictable, repeatable parts. Parametric models deliver that predictability because the same rules that define a panel in the model can feed CNC code, shop drawings, and assembly instructions. The result: faster on-site assembly and lower waste.

Industry analyses report modular and prefabrication methods can cut project time by 20–50% and lower costs by up to ~20% on some building types; other sources cite waste reductions in factory settings as high as 90% for certain material streams because off-site work is so precise. Parametric drafting is the bridge between the digital model and the factory workflow that achieves these numbers.

Performance-driven design

Parametric and algorithmic workflows let you run many quick experiments: change a louver angle, run a daylight study, adjust panel spacing, and measure the result. Rather than a single “best guess” design, teams can sweep parameters and optimize for temperature, glare, or solar gain. That changes the conversation from subjective “this looks better” to objective “this option reduces annual cooling load X% while keeping required U-value.”

Practically, teams using parameter sweeps can find solutions that improve comfort and lower operating costs without reinventing documentation practices. Parametric façades are a common application, both aesthetic and performance goals are addressed through automated panelization and iterative analysis.

Comparison Table

| Aspect | Parametric drafting | Algorithmic / Computational drafting | Generative design |

| Typical tools | Revit families, Solid modeling parametrics | Grasshopper, Dynamo, Python/C# scripts | Autodesk Generative Design, Grasshopper + optimization add-ons |

| Main output | Reusable families, controlled geometry, schedules | Programmatic geometry/assemblies, batch outputs | Multiple ranked design options (trade-offs) |

| Best for | Standardized components, quick changes, documentation sync | Complex layouts, adaptive systems, automated rules | Exploration when objectives are many and competing |

| Skill level | Revit authoring, parameters knowledge | Visual programming or scripting experience | Algorithmic + optimization expertise |

| Strength | Predictability, easy handoff, strong BIM integration | Flexibility, automation across many elements | Broad search of solutions; performance-driven |

| Weakness | Can be rigid for unusual geometry | Requires governance; scripts can become brittle | Heavy computational set-up and interpretation |

| Example use case | Window family with width/height/vent params | Façade grid adapting to column offsets and sun angles | Run 50 façade variants to balance cost vs daylight |

Contact Us For Error-Free Parametric & Algorithmic Drafting

When to Use Parametric and Algorithmic Drafting

There’s a moment on every project when the model starts fighting back. Someone moves a wall, and half the drawings go out of sync. A layout shifts, and suddenly every tag is wrong. That’s where parametric and algorithmic drafting stop feeling like fancy software tricks and start feeling like survival tools.

These methods aren’t for every job. Sometimes they’re overkill. But when repetition, bim coordination, or change start eating hours, a well-built parametric model earns its keep. It’s less about “innovation” and more about keeping chaos contained.

Use it when things repeat, shift, or need to talk to machines

Parametric and algorithmic tools thrive on patterns, anywhere a rule repeats or geometry gets reused. They turn messy repetition into clean automation.

You’ll want them most when:

- Repetition rules the job. Curtain walls, MEP racks, floor modules, anything that shows up again and again. You make the rule once and reuse it a hundred times.

- The geometry’s weird. Curved roofs, non-orthogonal grids, freeform facades. Things that can’t be drawn cleanly by hand without errors creeping in.

- Performance matters. Buildings chasing daylight targets, comfort scores, or energy ratings. Parameters let you tweak and test instead of guess and redraw.

- Mass-customization shows up. Modular housing, hotel rooms, or furniture runs where no two units are exactly the same. The model flexes but stays organized.

- You’re iterating fast. Early concept stages where design shifts daily. A few parametric rules make wild experimentation less painful.

- You need fabrication data. CNC, laser cutting, prefab molds, anywhere digital geometry needs to flow straight into production.

Imagine a precast façade with unique openings per floor. In a normal model, each change means hours of cleanup. In a parametric setup, one rule drives hundreds of variations, and drawings stay aligned without touching them manually.

When to skip it and stay simple

There’s no glory in over-engineering a small job. Some projects just don’t have enough moving parts to justify all that setup.

Stick to basic BIM or light scripting when:

- The job is small and static: a single storefront, a small addition, or something that will barely change.

- The budget is tight, and design decisions are locked in early.

- The client or GC can’t handle parametric models or prefers PDFs over BIM deliverables.

- There’s no repetition or data reuse. That means one-off details that won’t show up again.

Sometimes drawing manually really is faster. You don’t need a Dynamo graph to label five doors. Save your scripting energy for projects where the model earns it back.

The tradeoff: slow at first, fast forever after

Setting up parameters and scripts takes time; no way around that. The payoff comes later, when changes arrive. Then the same logic that slowed you down early becomes why you finish days ahead.

Here’s how the balance usually plays out:

| Stage | Traditional Workflow | Parametric / Algorithmic Workflow |

| Setup | Quick start, no prep | Slower start, rules take time to define |

| Design changes | Manual edits, easy to miss details | Automatic updates across model |

| Documentation | Risk of inconsistencies | Drawings sync themselves |

| Fabrication | Extra coordination needed | Direct model-to-machine link |

| Scaling | Adds more people | Reuse logic to expand fast |

| ROI | Quick payoff, low ceiling | Slow start, exponential return |

Tools, platforms and typical workflows used in industry

No magic wand makes every project smart overnight. What matters is picking the right tools, and using them in the right sequence. Below you’ll find how the industry deploys three major tool-sets and then two example workflows that show how everything ties together in practice.

Revit + Dynamo

If your project is already built in Autodesk Revit, then adding Dynamo is low-risk and high-leverage. Dynamo sits inside Revit, lets you hook logic to model elements, and automates manual work. In practice, this means:

- Automatically placing tags or room numbers on many elements instead of one-by-one

- Synchronizing shared parameters across linked models or updating family types en masse

- Generating sheet sets, plan views or sections based on naming rules and templates

- Preparing fabrication-friendly outputs from the model (e.g., placing shop sheets, filtering families, exporting to spreadsheets).

In one case study, teams using Dynamo saved over 90 % of the time they would have spent on repetitive tasks like sheet creation and renumbering, simply by routing those tasks through scripts and logic.

Another contractor used Dynamo to tag all ducts and pipework automatically, creating clean deliverables and reducing manual error. On big MEP infrastructure jobs, that kind of accuracy matters.

So if your model is in Revit and your workflow has repeating elements or frequent documentation updates, Revit + Dynamo is often the logical starting point.

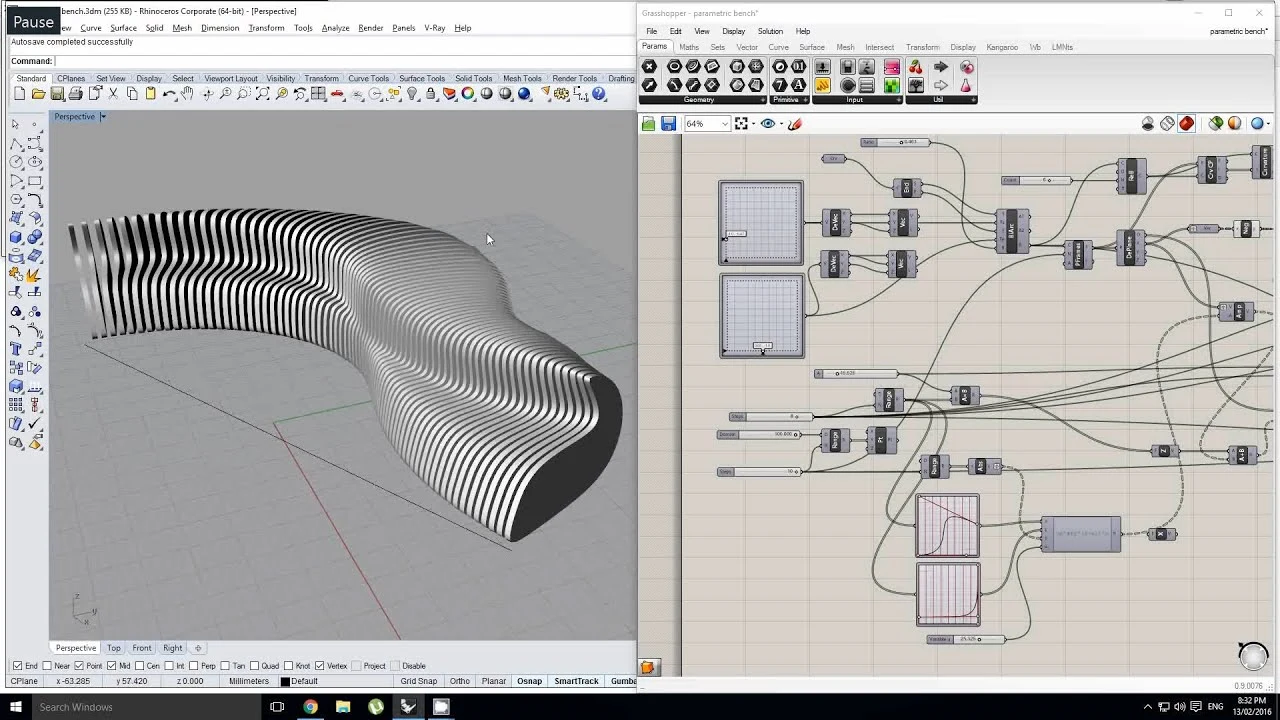

Rhino + Grasshopper

When your project includes unusual shapes, you’ll often see Rhino + Grasshopper in play. Rhino gives you the geometry freedom, Grasshopper gives you the logic to manipulate it. Use cases include complex roof forms, panel systems that wrap curves, or structural components where standard grids don’t make sense. Rhino’s website states explicitly that it “enhances a team’s ability to execute creative building form.”

Within that environment you’ll also often add plugins. For example:

- geometry analysis or structure engine plugins (Karamba, Kangaroo) for form-finding;

- fabrication plugins (RhinoFabSuite or similar) to generate cut-lists, machine code or CNC curves;

- panelization routines that take the curved surface, break it into panels, apply rules (like max panel size 2.4 m, max deviation, anchor spacing) and output drawings or machine path data.

If you’re doing something non-orthogonal, or your façade isn’t just “windows in a grid,” then Rhino + Grasshopper becomes the toolset to reach beyond standard BIM families and documentation.

Other tools

Beyond the two major fronts above, modern workflows frequently include additional layers: custom code, cloud tools, interoperability bridges. Examples include:

- Python or C# scripts embedded in Dynamo, or standalone add-ins for Revit.

- Cloud services or APIs like Autodesk Forge or Rhino. Compute

- Interop plugins such as Rhino.Inside.Revit (allowing Rhino geometry inside Revit) or IFC export/import

- Custom cloud-based dashboards that monitor model health, parameter compliance, or fabrication status in real time.

These tools add depth. They don’t replace your core platform; they integrate it. They matter when you need scalability, cross-discipline data flow, or a direct link to fabrication.

Workflow examples

Here are two real-world narrative workflows. Follow them step-by-step and you’ll see how tools merge into the project process.

Workflow A: Architectural façade project

Concept → parametric massing (Grasshopper) → performance analysis → convert to BIM (Rhino.Inside → Revit) → Dynamo‐driven documentation → fabrication output (CNC/ShopDWG/IFC).

In plain terms: start with form in Grasshopper, refine via daylight or energy logic, and move geometry into Revit via Rhino. Inside, build families and sheets using Dynamo, then generate fabrication drawings and data. This chain keeps the original logic alive from concept to shop floor.

Workflow B: MEP prefab flow

Parametric routing rules → clash-avoidance automation → fabrication packages.

Here the tools might be Revit plus Dynamo (or scripts) to route MEP racks based on parametric rules (clearances, modules, hanger spacing), then run automated clash checks, then produce fabrication packages (cut lists, BOMs, tags). The parametric logic reduces coordination time and just-in-time errors.

How CAD Drafter Helps: Services & Value Proposition

For more than 25 years, CAD Drafter has been working behind the drawings, translating design ideas into models that behave. Not static lines, but living systems that move, update, and feed fabrication directly. The firm started as a small drafting studio in the U.S. and grew into a technical partner for architects, engineers, and builders who need smarter workflows without reinventing their entire process.

We don’t sell software. We build what connects it.

What we do

Every project has its pressure points. These include late design changes, coordination drift, or shop drawings that fall behind schedule. CAD Drafter’s services aim straight at those weak spots:

- Parametric family creation: Clean, rule-based Revit families that flex and update without breaking. From door libraries to entire façade systems.

- Dynamo scripting & automation: Custom scripts that automate documentation, parameter control, and MEP layout tasks, cutting repetitive work by hours or even days.

- Grasshopper definitions: Adaptive façade, panelization, and pattern systems driven by performance or fabrication logic.

- BIM parametric integration: Linking Rhino, Revit, and fabrication data into one consistent parametric model, ready for IFC or shop drawing output.

- Shop-drawing generation & fabrication data prep: Automated drawing sets, schedules, and CNC-ready exports that reduce manual re-entry errors.

- Team training & support: Workshops that bring in-house staff up to speed, using your real projects, not generic examples.

We’ve helped teams shift from red-pen markups to live, rule-driven models where one parameter change updates a dozen sheets automatically.

FAQs

What is the difference between parametric and algorithmic drafting?

Parametric drafting is about relationships. You tell the model how parts relate. For instance, a door stays centered, a beam follows a floor level, and a window resizes based on width. It’s a rule inside geometry. Algorithmic drafting goes a step further. It doesn’t just react, it thinks through possibilities. You set logic and the model generates outcomes on its own: hundreds of layout variations, grid patterns that shift with site conditions, or façade panels that adapt to solar angles.

Parametric is “if this, then that.” The algorithm is “let’s find the best version of this.”

When should a contractor request parametric deliverables from a design team?

When the job has repetition, coordination complexity, or tight tolerances. Curtain walls, MEP racks, modular interiors, anything with patterns or preassembly. Requesting parametric deliverables early lets you lock in rules before construction drawings pile up.

It’s especially useful when changes are still flying. A single parameter tweak can ripple through drawings, saving redlines later. If the project’s static, it’s overkill. If it’s moving fast and involves multiple trades, it’s insurance.

How does parametric drafting help with prefabrication and modular construction?

Prefab depends on precision. Parametric drafting delivers it. When parts are defined by parameters instead of static dimensions, fabrication data stays in sync with the model. You can change a module width or window spacing and regenerate shop drawings instantly. That logic extends down to manufacturing. CNC files, cut lists, and assembly drawings all come straight from the same rules.

For modular builders, that’s gold: fewer surprises on-site, tighter coordination between trades, and faster assembly.

What are the risks of parametric modeling and how are they managed?

Every system that automates work carries risk, mostly human ones. Poorly defined parameters can cascade into broken families or geometry that refuses to behave. Overcomplicated scripts can trap a team in technical debt.

The way to manage it? Keep the logic simple. Document it. Test every rule on a small scale before rolling it across the model.

Can parametric drafting reduce construction costs and delays?

Yes! When it’s used for the right problems. Parametric systems don’t save money by being flashy. They save it by cutting rework, coordination time, and duplicated effort. One change updates a dozen sheets. One logic set creates hundreds of parts.

On past projects, contractors using parametric workflows have seen measurable results: fewer RFIs, reduced field conflicts, and faster shop-drawing turnaround.

Savings show up quietly, in fewer emails, shorter meetings, and drawings that don’t need to be patched at the last minute.

Which tools are best for parametric drafting in construction?

There isn’t a single winner; it depends on the shape of the problem.

- Revit + Dynamo for BIM automation, documentation, and MEP systems.

- Rhino + Grasshopper for curved surfaces, façades, and geometry that refuses to fit into boxes.

- Custom scripts (Python, C#, Forge APIs) for data-heavy workflows or cloud automation.

Most firms use two or three together. The smartest setups make them talk to each other

The Final Takeaway

Parametric and algorithmic drafting aren’t buzzwords. They’re tools for teams that want to move faster without breaking things. When used well, they turn design intent into repeatable logic. That means drawings that fix themselves, schedules that stay in sync, and fabrication data that fit on-site

That’s what CAD Drafter has been building for over 25 years: systems that hold up under pressure. If you’re curious where parametric drafting could make a difference in your workflow (maybe a small pilot project, maybe a full automation strategy), reach out. We can walk through your current setup, identify opportunities, and show real case studies from teams already doing it.

No fluff. No pushy sales. Just practical insight and proof that your model can work harder for you. Contact CAD Drafter to start the conversation or request a tailored case study showing how parametric logic reshapes project delivery from day one.