What Are Shop Drawings And Who Needs Them (Contractor’s Guide)

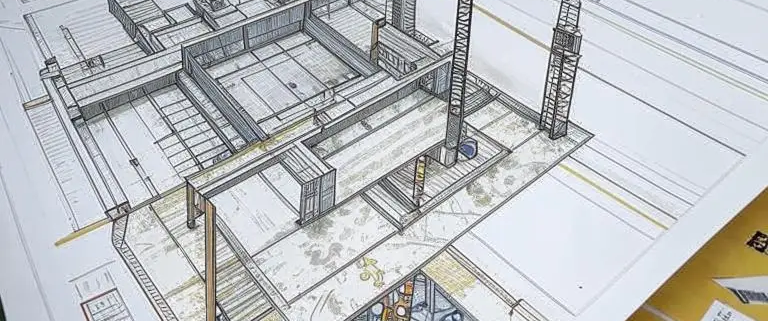

Walk onto any active job site and look around. Every beam, every duct, every custom-cut piece of steel that fits perfectly into place began life on a sheet of paper. Not the architect’s blueprints, but something far more detailed. Those are shop drawings, the behind-the-scenes documents that quietly decide whether a project runs smoothly or grinds to a halt.

A recent study by Robridgit found that more than poor design coordination leads to rework that adds 52% to the cost growth and 9.82% to the schedule growth. Most of those start with incomplete or inaccurate shop drawings. It sounds minor until you’re the one standing there with a crane waiting and a steel column that doesn’t match the connection plate.

Shop drawings translate big design ideas into fabrication reality. They show exactly how parts will be made, welded, or bolted together. They tell installers where everything goes and help the architect confirm that the final build will actually work. In short, they keep the chaos in check.

If you want to see what a clean, professional set looks like, get in touch with Cad Drafter. We’ll send you a free shop drawing template or sample so you can compare it with your current process and spot the difference. Keep reading to understand more about the shop drawing definition and uses.

What Are Shop Drawings? (Definition & Purpose)

If you ask ten people on a job site, “What are shop drawings?” you’ll probably get ten slightly different answers. The simplest and most accurate one is this:

Shop drawings are detailed construction documents created by contractors, subcontractors, or manufacturers that show how specific components will be fabricated, assembled, and installed.

That’s the formal shop drawings definition. But in practice, they’re much more than that. These drawings are the missing link between an architect’s design and the work that happens in the field. The architect defines intent. The shop drawings define execution. They turn broad design ideas into measurable, buildable details. These include actual dimensions, materials, tolerances, and connection points.

A good set of shop drawings has one job: eliminate uncertainty before fabrication starts. That’s why accuracy matters more here than almost anywhere else in the project documentation chain.

The purpose of shop drawings goes beyond coordination. They ensure that the work fabricated off-site matches the architect’s intent and fits perfectly once delivered. They help prevent field conflicts, minimize delays, and reduce expensive rework. In short, shop drawings keep design integrity intact while keeping construction practical and efficient.

If you want to see what a professionally developed set looks like, contact Cad Drafter. We can walk you through real examples and show how proper shop drawings keep complex builds running smoothly.

Shop Drawings vs Design Drawings: Key Differences

If you walk through any construction office, you’ll see two kinds of drawings pinned to the wall. One set shows the dream. The other shows how that dream is built. That’s the simplest way to understand shop drawings vs design drawings.

Design drawings come first. Architects and engineers produce them to capture the look, layout, and intent of a project. They describe what the structure should be, how it should perform, and the standards it must meet. Shop drawings arrive later. These are created by contractors, fabricators, or manufacturers who turn that intent into a buildable plan. Each bolt, weld, bracket, and dimension is defined there.

Some people use the phrase shop drawings vs construction drawings to compare the two, but construction drawings usually refer to the full design package issued for bidding or permits. Shop drawings drill down into the specifics that make the project possible in real life.

Here’s a quick way to see the difference:

| Category | Design Drawings | Shop Drawings |

| Main Purpose | Show overall design intent and performance | Show exact fabrication, assembly, and installation details |

| Prepared By | Architect or engineer | Contractor, subcontractor, or manufacturer |

| Focus | Aesthetics, function, and compliance | Practical construction and material coordination |

| Detail Level | General dimensions and layouts | Precise measurements, joints, and connections |

| Responsibility | Design team defines expectations | The trade team ensures constructability and accuracy |

In simple terms, design drawings explain what should exist, and shop drawings explain how it will exist. Both must align, or the project starts slipping before the first piece is fabricated.

If you want to see how these two document types complement each other in practice, reach out to Cad Drafter. We can walk you through real examples that show how design intent becomes a buildable reality.

Who Prepares Shop Drawings & Who Needs Them? (Contractor, Subcontractor, Manufacturer)

When people first hear about shop drawings, they often assume architects handle everything. In reality, the work belongs to the teams that actually build and supply the materials. The architect’s job is to define intent. The contractor and their trades are responsible for showing how that intent becomes something physical.

According to the AIA A201 Contract and ConsensusDocs 200, the contractor is ultimately responsible for preparing, reviewing, and submitting all shop drawings to the design team. But the creation itself usually happens within the specialized trades (subcontractors, manufacturers, or fabricators). Each one adds the technical detail for their specific scope of work.

Here’s how that usually breaks down:

| Role | Main Responsibility | Examples of Shop Drawings They Produce |

| General Contractor | Reviews and coordinates drawings from all trades before sending them to the architect or engineer. Ensures accuracy and consistency with contract documents. | Coordination drawings, composite MEP layouts |

| Subcontractor | Prepares discipline-specific drawings that reflect actual installation conditions and materials. | HVAC layouts, plumbing risers, electrical conduit plans |

| Manufacturer | Provides detailed fabrication drawings and product data for pre-engineered or custom items. | Curtain wall systems, elevators, and mechanical units |

| Fabricator | Converts design intent into production-ready detail for items made off-site. | Structural steel connections, millwork, metal stairs |

What to Include in a Shop Drawing (Checklist & Template)

A well-prepared shop drawing is more than a sketch. It’s the backbone of a smooth construction process. Every line, note, and symbol must tell the fabricator or installer exactly what to do. The goal is clarity. When done right, no one on the job site should have to guess.

According to the AIA A201 and LA County Public Works drafting standards, each trade must submit detailed and coordinated shop drawings before any fabrication begins. So, what should a shop drawing include? Use the following contractor-ready checklist to make sure your submission meets professional and contractual requirements.

Shop Drawing Checklist

Each drawing set should contain the following key elements:

1. Title Block

Includes project name, sheet number, trade name, date, and contact details for the preparer.

2. Drawing References

Cite related design drawings, detail numbers, and specification sections. This keeps reviewers aligned with the project documents.

3. Scale and Orientation

Use standard scales and provide north arrows or section cut indicators for clarity.

4. Dimensions and Tolerances

Every measurement must be exact. Include both overall and component dimensions, plus fabrication tolerances.

5. Materials and Finishes

List materials by type, grade, and finish. Include manufacturer references or approved alternates.

6. Connection Details

Show bolts, welds, joints, anchors, and assembly interfaces. These must be coordinated with adjacent trades.

7. Bill of Materials (BOM)

Provide a clear list of parts and quantities. Also, highlight item codes to support procurement and fabrication.

8. Fabrication and Installation Notes

Outline any special handling instructions, field adjustments, or coordination points with other systems.

9. Manufacturer Data Sheets

Attach product cut sheets, testing certifications, and compliance documents as required by the contract.

10. Quality Assurance Signoff

Include signature blocks for the preparer, reviewer, and approving engineer or architect. This establishes accountability through the submittal chain.

Free Shop Drawing Sample and Template

If you want to skip the setup process, we offer a free shop drawing template for contractors, subcontractors, and fabricators. It includes a ready-to-edit PDF and DWG format that you can adapt for your next submittal.

This shop drawing template download is designed to follow AIA and ConsensusDocs standards and comes pre-formatted with all required sections.

To get your copy, simply contact Cad Drafter and request our free shop drawing sample.

We’ll send you the template and a sample drawing so you can see exactly how a professional submission should look. It’s practical, easy to use, and built to help your drawings pass review the first time.

How to Review Shop Drawings (QA/QC Checklist for GCs & Engineers)

Knowing how to review shop drawings can stop problems before they start. It is quality control in motion. Small omissions become big headaches on site. Catch them early and you save time, money, and stress.

Use this shop drawing review checklist when you open a submittal. Read it out loud if you must. Good reviews are deliberate and a little stubborn.

Title and references

Confirm project name. Confirm sheet numbers and spec sections. Check the submission date. Version control matters. Old revisions create clashes.

Match to design and specs

Cross-check dimensions, elevations, and material callouts against the contract drawings and specs. If it does not line up, flag it.

Fabrication details

Inspect joints, weld sizes, fastener types, and finish notes. Missing tolerances are a red flag. Sketches without specifics are risky.

Trade coordination

Look for clashes between mechanical, electrical, and structural. Run a quick overlay or a 3D clash check when you can. A single interference can stop an install.

Field verification

Confirm that critical dimensions were verified in the field. Notes that say verify in field without proof lead to rework. Don’t accept vague statements.

Codes and standards

Check compliance with applicable codes, ADA, and referenced standards. If a substituted product is used, verify it is approved.

RFI triggers

Anything unclear becomes an RFI. Ask early. Short questions now beat long delays later.

Clear comments

Mark items as Reviewed, Revise and Resubmit, or Rejected. Keep comments actionable and traceable.

Approve with intent

Approval means conformity to design intent, not a blanket acceptance of errors. Be precise about what you approve.

Follow this shop drawings QA/QC routine, and reviews stop being guesswork. They become a tool. A useful one.

Request a free sample

Tools & Software for Producing Shop Drawings (CAD, Revit, Tekla, Advance Steel)

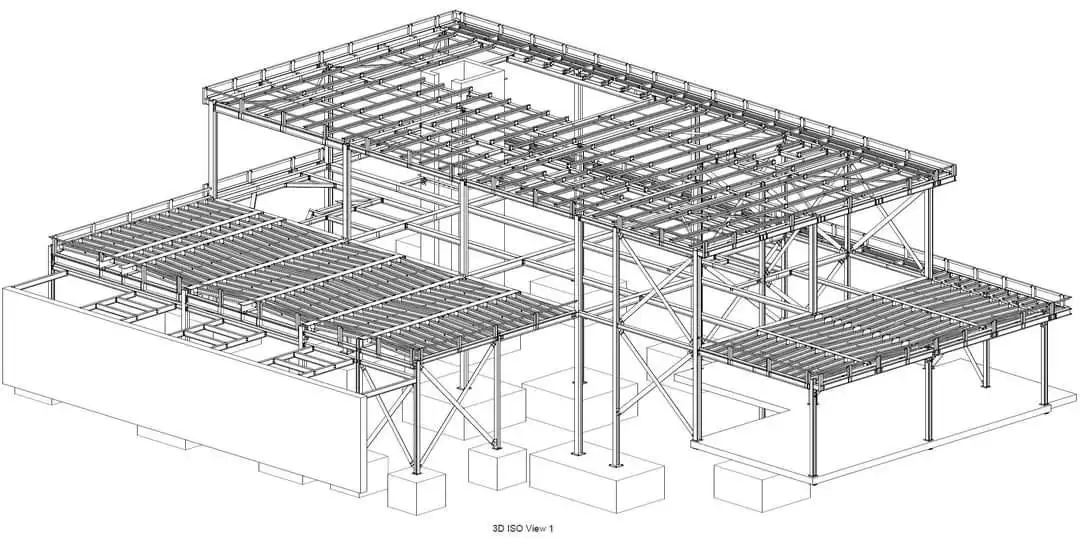

Good shop drawings depend on the right tools. The software you use determines how clearly you communicate. Besides, it helps assess how easily others can coordinate with you, and how quickly revisions move through the pipeline. Some tools are simple and fast. Others are powerful but require more setup. The key is choosing what fits your project.

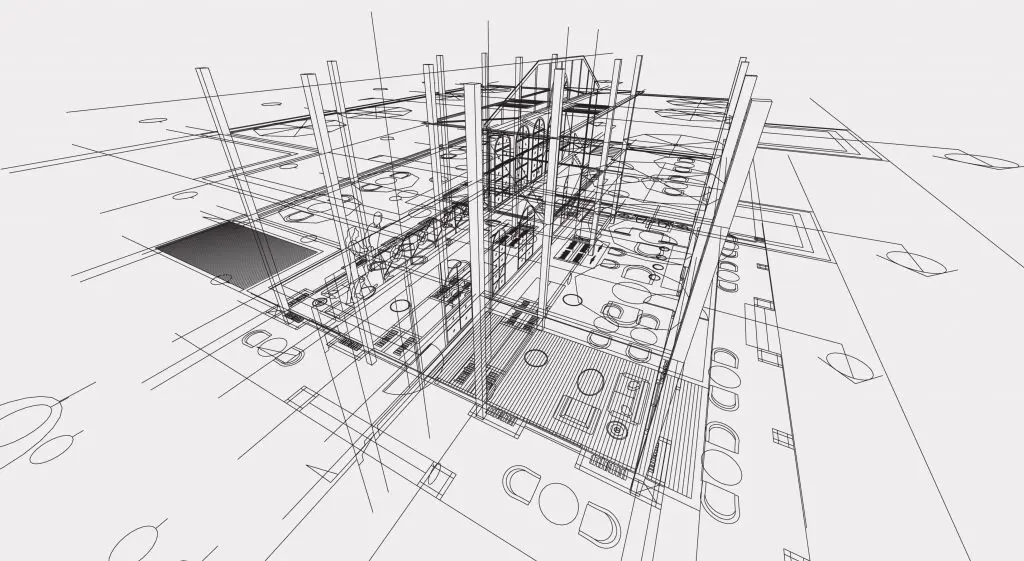

In the past, every shop drawing lived in 2D. Today, that has changed. Many firms now use 3D models because they catch mistakes early and help avoid field conflicts. Still, 2D has its place. It’s faster for smaller scopes and lighter trades.

Here is a quick overview of the most widely used shop drawing software in the construction and fabrication world:

| Software | Best For | Highlights | File Compatibility |

| AutoCAD | General 2D drafting and detailing | Ideal for millwork, MEP layouts, and fabrication details. Easy to learn and extremely versatile. | Native DWG, exports to PDF and DXF |

| Revit | BIM-based coordination and MEP/structural modeling | Great for extracting 2D sheets from 3D models. Automatic updates when model changes. | RVT, IFC, DWG |

| Tekla Structures | Structural steel and precast concrete | Produces fabrication-grade drawings with bolt, weld, and connection data. | IFC, DWG, CNC-compatible |

| Advance Steel | 3D structural detailing on the AutoCAD platform | Automates BOMs and CNC output. Excellent for shop-level steel work. | DWG, NC, IFC |

Common Mistakes and How to Avoid Them (Contractor’s Checklist)

Every project begins with confidence. The plans look perfect, the timeline makes sense, and the trades are ready. Then someone spots a small error in a shop drawing and suddenly everything stops. That is how most shop drawing mistakes start. Tiny details, big consequences.

So, what actually goes wrong?

● Outdated References

One of the most common shop drawing errors is using an older revision of design drawings. It sounds obvious, but it happens all the time. Always confirm your sheet references match the latest set issued by the architect or engineer.

● Incorrect Dimensions

Dimensions are the heartbeat of a drawing. Even a few millimeters off can throw off fabrication. Before submitting, check your layout against design documents and site measurements. If something feels off, it usually is.

● Missing Bill of Materials (BOM)

A missing bolt or bracket may not sound like much, until the shop halts production waiting for parts. Always attach a full material list that includes quantities, finishes, and supplier info.

● No Coordination Between Trades

Ducts meet beams, pipes cross electrical trays. Prevent that early. Use Revit, Navisworks, or similar coordination tools to detect clashes before the drawings go out.

● File Chaos

Ever opened five versions of the same sheet and not known which one is correct? That is file chaos. Name your drawings properly. Keep a single source of truth for approved sets.

● Skipping the Final QA Pass

Everyone is busy. Still, skipping that last in-house review is a mistake that will come back later. A quick internal QA before submittal saves time and arguments later.

Here’s a compact reminder list you can keep near your workstation:

- Confirm design and spec references

- Verify every dimension and scale

- Double-check the BOM

- Coordinate drawings across trades

- Approve only the current version

Avoiding shop drawing problems is not complicated. It just requires discipline. A few extra minutes of checking can prevent a week of rework. For contractors who handle multiple trades, consider setting up a shared pre-submittal review checklist. Or, if you want a professional eye on your drawings, Cad Drafter can review, correct, and prepare them before you submit.

Outsourcing Shop Drawings: When to Hire a CAD Shop Drawing Service

Not every contractor or fabricator has the time or in-house staff to create detailed submittals. That’s where shop drawing services come in. Outsourcing lets your team stay focused on the build while experienced drafters handle the technical side.

Here’s when it makes sense to bring in outsourced shop drawing services:

- You have a tight deadline or multiple trades submitting at once.

- Your team lacks specialized CAD or BIM expertise.

- The project requires coordination between Revit, AutoCAD, or Tekla platforms.

- You need professional QA/QC before submission to the design team.

A good CAD shop drawing service delivers fully compliant, ready-to-review drawings. Expect a clear workflow that includes:

| Scope Item | Typical Deliverable |

| Drawing Production | 2D/3D shop drawings, coordination models |

| Material Data | BOM, specification references |

| QA/QC Review | Compliance with AIA and project standards |

| Revision Support | Updates based on review comments |

| File Formats | DWG, PDF, IFC, or Revit files |

If you are running short on time or resources, Cad Drafter can take over the drafting load. Our team provides fast, accurate, and fully coordinated shop drawings tailored to your project needs.

Visit our Shop Drawing Services page to learn how we can support your next submittal cycle.

FAQs

What are shop drawings?

They are the detailed working drawings made by the trade or fabricator that show exactly how a component will be built and installed. Think of them as the construction recipe that follows the architect’s design.

Who prepares shop drawings?

Subcontractors, manufacturers, or fabricators usually create them. The general contractor coordinates the package before it goes to the design team.

How long do shop drawings take?

It depends. Small, routine sets may be ready in a few days. Complex coordinated systems can take several weeks from first draft to final approval. Project scope and reviewer turnaround drive the schedule.

What should a shop drawing include?

Clear title block, referenced design drawings, exact dimensions, materials, connection details, bill of materials, and any fabrication or installation notes. Attach manufacturer data where required.

Why do shop drawings matter?

They resolve practical conflicts before material is cut or ordered. Good shop drawings cut RFIs and on site rework. Bad ones create delays and extra costs.

Are shop drawings the same as construction drawings?

No. Construction drawings show overall design and intent. Shop drawings zoom in on fabrication and installation detail for specific components.

What software is used for shop drawings?

Common tools include AutoCAD for 2D, Revit for BIM workflows, Tekla for steel and precast, and Advance Steel for detailed steel output. Choose based on trade and coordination needs.

Can shop drawings be created in 3D?

Yes. 3D models speed coordination and reveal clashes that 2D alone can miss. Use 3D when multiple trades occupy the same zone.

Do owners get copies of shop drawings?

Sometimes. Typically, the contractor and design team manage the process, but owners may request copies for records or quality assurance.

Can I outsource my shop drawings?

Absolutely. Outsourced CAD shop drawing services are common when in-house capacity is limited or schedules are tight. Quality vendors provide production, QA, and revision support.

Conclusion

Shop drawings turn a design into reality. They catch the small things that otherwise become big problems. If you want cleaner submittals, fewer RFIs, and faster approvals, get help that knows the details. For shop drawings help, to hire a shop drawing service, or to see a real sample, contact Cad Drafter. Request a free sample and a no-obligation quote. See how a professional package looks and decide from there.