Complete Project Overview

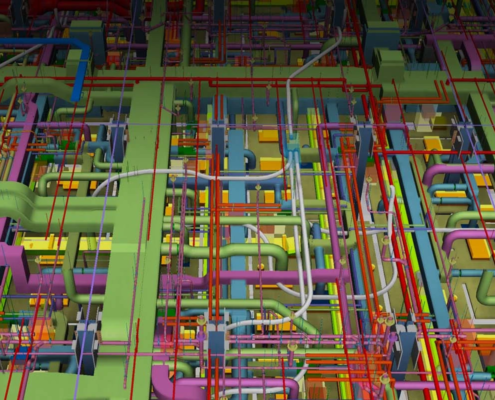

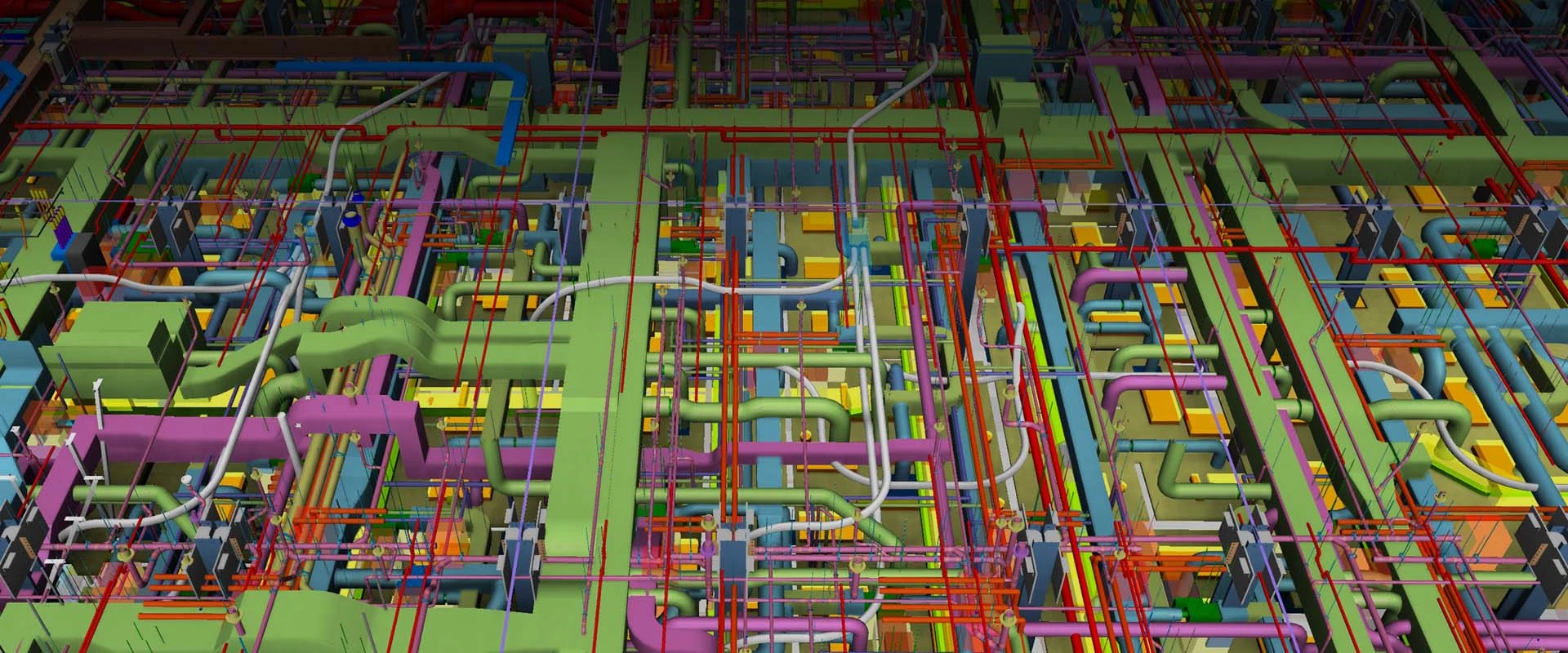

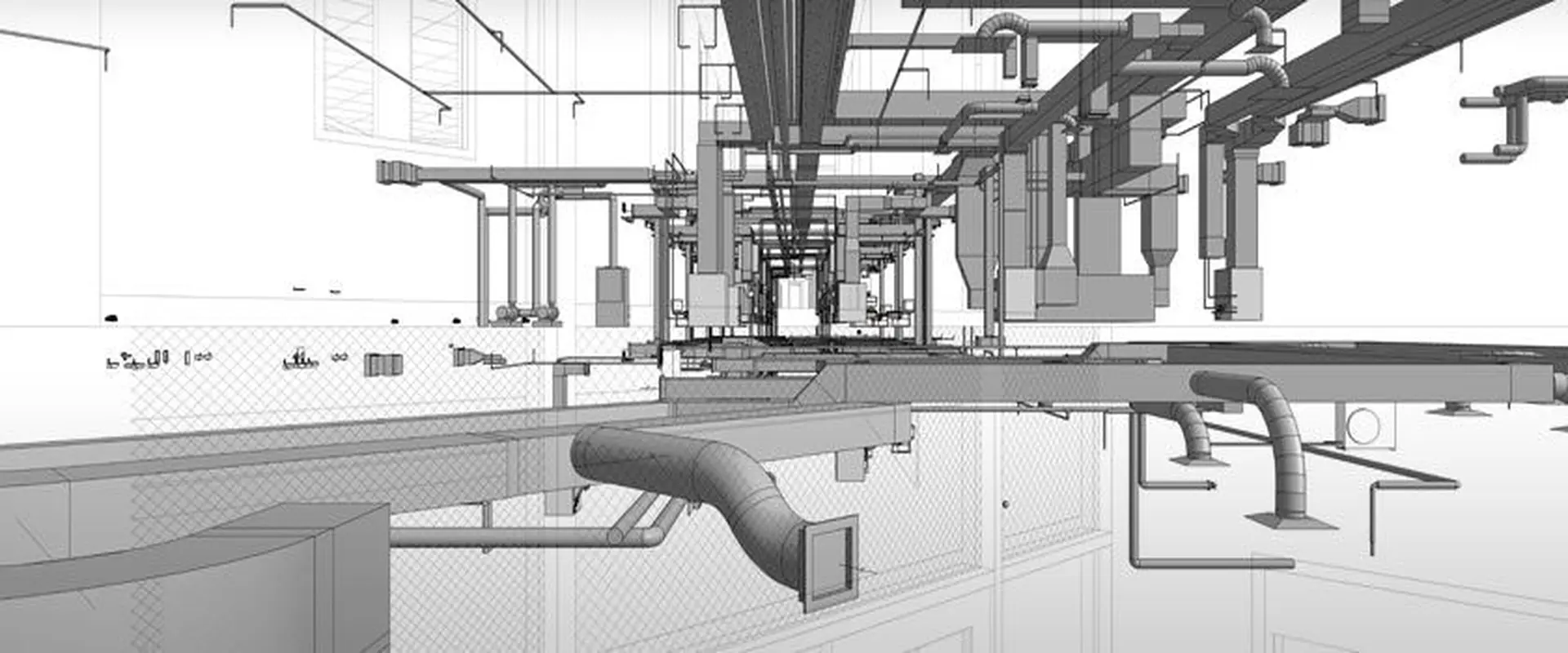

At HZ Biomedical Research Center in Boston, our Revit coordination turned complexity into usable lab real estate. Eight specialists mapped MEP systems with granular care. Eleven months of iterative drafting, clash resolution, and on-site checks trimmed wasted space, improved routing, and made maintenance straightforward. Labs became more flexible. The final result was an 18% gain in usable efficiency. This saved time, lowered costs, and left researchers with a smarter, safer place to work daily.

Here’s Why They Called Us!

The university board needed precision, not guesswork. Their labs required dense MEP systems tucked into tight footprints without slowing research. They called us because we speak “Revit fluently” and could guarantee coordination that cut waste before construction even began.

Challenges Faced By The Team

No research facility comes simple, and this one kept us on our toes. First, biomedical labs demand strict ventilation, pressure controls, and redundant safety systems. Every duct and valve had to earn its place. Coordinating those with structural beams created conflicts that standard templates couldn’t solve. Then came the client’s evolving requests: more lab benches, expanded cold storage, added cleanroom features. Each change forced a redraw, often mid-coordination. File sizes ballooned; syncing models across multiple stakeholders slowed daily progress. Local Boston regulations added another twist, with safety codes shifting mid-project. Instead of halting momentum, we leaned into communication. Daily check-ins, clash detection sweeps, and agile updates kept the team aligned. Hard problems, sure, but each pushed us toward sharper, cleaner solutions.