How Much Does 3D Printing Services Cost?

If you are a designer, hobbyist prototyper at home or a business dealing with manufacturing products, you need 3D prints. From the initial designs to the final manufacturing, prototypes help in reducing errors and bring life to your vision. But, the most concerning question that comes to mind is How much do 3D printing services cost? In this blog, we will break down the cost of 3D printing services in detail so that you can plan smarter and make better decisions.

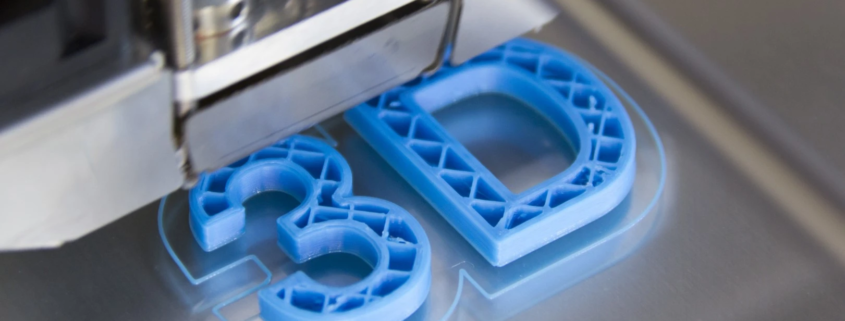

Importance of 3D Prints

Have you ever seen a 3D printing video making toys, and think that it would be fun to do a practical for this? The exciting news is that, yes, you can do it with the help of a 3D printer. Besides fun and entertainment, 3D printing has also revolutionized designing, gaming, manufacturing, and many other industries. Now, you can quickly change the digital ideas into physical models. Large businesses use prototypes and 3D prints for accurate manufacturing by reducing material wastage. Further, these prints also save time in manufacturing by providing authentic details. In short, we can say that 3D printing is the shortest and easiest way to convert your ideas into reality.

Average Cost for 3D Printing Services

The cost of 3D printing can range from one dollar to a thousand dollars for commercial projects. If we talk about the cost per hour, then it may be anywhere in between $1-$3. The cost depends on many factors. So, to know a detailed cost analysis for 3D prints, let’s discuss all these factors.

Factors Affecting the 3D Print Cost

The following are the main factors that may affect the cost

Material Cost

The material you use for 3D prints makes a great impact on the overall cost. Two main types of materials are used for printing purposes

ResinsSome 3D printers use liquid material known as resins. These are used mostly in SLP printing. They are available in many types and qualities. You can choose the one according to your demand. The standard lessons with average quality cost $35 for 1 kg, while the high-quality resins are expensive and cost over $100 for 1 kg. |

FilamentsSome printers use plastic strings, which are known as filaments. This filament printing material is used in SLS and other printers. They are also of different types of filaments, varying in quality. Standard filaments cost around $15 to $20 for 1 kg, while colour-changing filaments are expensive and cost about $40 for 1 kg. |

Now the question is whether you go for the high-quality materials or standard-quality resins and filaments. Well, the answer to this is that the high-quality materials will be good for your 3D prints, but it doesn’t mean that you are bound to choose the high-quality materials. If you have a low budget, then you must go with the standard quality materials. They also provide good results of 3D prints.

HomePrinting Vs Outsourcing

Another factor which affects the cost of 3D prints is whether you are home printing or outsourcing it.

Home Printing CostIf you have a printer at your home, then the only cost you bear will be the cost of the material and electricity. The consumption of electricity ranges between $0.10 $0.30 per hour. |

Outsourcing CostIf you are outsourcing 3D printing services, then the cost may vary from company to company. The average cost for 3D printing services may vary from $1 for small objects to thousands of dollars for large commercial projects. |

If you require 3D prints frequently in a high volume, then it is a good option for you to make a one-time investment on purchasing a 3D printer at your home/workplace and reduce the cost of outsourcing. But if you have low volume and occasional projects, then you must choose outsourcing.

Investment Cost

If you are a 3D printing service provider, then you must consider this cost and adapt your charges so that you can break operational cost to earn a profit. Let’s suppose you have purchased a 3D printer worth $2000, which has a lifespan of 20 years, so you have to add $1 for each of your customer charges to break your investment.

Operational Cost/Electricity Cost

The printer runs on electricity, and electricity is not free of cost. If you are using home printing for occasional 3D prints, then the electrical cost is not a big concern. However, if you are running a large busines, then the operational cost of your printer in terms of electrical consumption will be higher. A 3D printer consumes 50-70 Watts of energy per hour. The rate of electricity depends on your location. In some State, the electricity rates are high while in others they are low. For a better understanding, if your 3D printer continuously operates for 8 hours a da,y, then it consumes electricity that will cost you less than 10 cents.

Labor Cost

3D printers are not automatic. Labour is required to control their functions. If you hire labor, then you have to pay for their time and management skills. The labour rate depends on the experience, location, and company size. The average early weight for a 3D printer supervisor in the USA is anywhere between $18 $50 per hour. These 3D printer supervisors are responsible for supporting printing, packaging, and delivering the prints.

Repairing Cost

A printer is a machine, and continuous usage of it can cause damage to some parts, such as belts, nozzles, cooling fans, and thermistors. You should add the repair cost of hardware to your upfront investment cost.

Model Cost

The 3D model cost makes a great impact on the final calculation of 3D printing cost. There are three possible reasons for the 3D model

- The client provides you

- You have to get it from a free resource

- You have to design it by yourself

If the client asked you to design the 3D model, then you must add the design services charges. Customised 3D model design services charges vary between $20 $200 per hour. Besides customization, the volume and complexity of the model also impact the charges. For example, complex designs with small intricate details may require more support and slow the printing process, adding to the cost.

Profit Margin

The last factor is the profit margin. It may vary from business to business. Businesses with many years of experience and good reputation in the market usually specify a certain profit ratio. If you are new to this business, we advise you to keep your profit margin at a moderate fair share to offer an acceptable quotation for 3D printing services to your clients.

A Few Other Materials And their Cost

Materials |

Cost |

| Disappearing Glue Stick | $2 – $5 |

| Sandpaper Assortment | $5 – $15 |

| Cleaning Kit | $10 – $25 |

| Acrylic Paint Set | $8 – $25 |

| brushes | $5 – $15 |

| Isopropyl Alcohol (IPA) | $3 – $10 |

Total Cost for 3D Printing Services

The following are the factors that will add up to calculate the final cost for 3D printing services

Printing Material Cost+ Investment Cost+ Operational Cost / Electricity Cost+ Labor Cost+Repairing Cost+ Model Cost+ profit margin = Total cost for 3D printing services

Tips and Strategies to Reduce the Cost of 3D Printing

The following are some Strategies and tips that can help you reduce the overall cost

Choose the Right Printer

Never go for an extraordinary printer with too many features without observing the requirements of your projects and work. Analyse your project requirements carefully and then choose the printer that has all the necessary features essential to meet the needs of your project.

Choose the Right Material

Choosing the right material according to the need of your prototype not only prevents you from extra spending, but also reduces the wastage of material. Therefore, always evaluate which material is suitable for your design and choose wisely.

Make Bulk Purchases

If you need to print large-scale projects frequently, then we advise you to purchase the materials in bulk. It will give you a chance to avail the offers through volume discounts and will also reduce the shipping cost for you. Purchasing the materials in bulk not only reduces the cost but also ensures that you have sufficient printing material for your backup.

Explore 3D Printing Costs

3D Printing Cost Calculator

These calculators are software that automatically processes the process of cost calculation for 3D printing.

3D Printing ProIt is the most used calculator with a lot of features. It offers too many features that no other software offers. One of them is tax calculation |

OMNIIt is a fast 3D calculator. It gives you material costs and gives instant calculations. |

Shatter BoxIt is available with a lot of features. The most important feature is that you can download it and use it in Pc. |

3D AddictIt is also very important software and is available in the market with a lot of features. This calculates all expenses for 3D printing services to give you a final analysis of the cost. |

DIY or Outsourcing 3D Printing Services: Which One is Better for Cost Optimization?

Choosing between DIY and outsourcing depends on many factors. Some of them are projects, frequency, printer usage, skills to handle the whole process, etc. If you have to work on many projects, then a DIY printing system is best for you, but if the work frequency is low and you have to work on a few projects, then outsourcing is the best option for you. Choosing DIY without having proper expertise and skills can cost you more in terms of material wastage and rework. Therefore, it is essential to get proper knowledge and skills to handle the printing system before operating it. Many guides and tutorials on YouTube are also available for the guidance of printer operations.

Conclusion

A 3D printing system is beneficial for creating physical models of digital prototypes. The cost of printing depends on various factors. Some of them are material selection, 3D design, labor cost, electricity charges, operational cost, and profit ratio. Large-scale commercial businesses opt for DIY printing systems due to the heavy load of work. It saves their cost, and they have to spend on a one-time investment for the printer purchase. Maintenance and repairing hardware are some other additional costs for a DIY printing system, while outsourcing 3D printing services is suitable for small-scale businesses.

Frequently Asked Questions

What is the average cost of a 3D printing system?

The average cost may vary from $1 to thousands of dollars for various small models to large-scale business projects.

What factors affect the cost of 3D printing?

Printing Material, labor cost, electricity charges, operational cost, maintenance cost, and profit margin are some factors that may impact the overall cost of the printing system.

DIY or outsourcing: Which is best for 3D printing?

It depends upon various factors. DIY printing is best for large businesses, while outsourcing is best for small-scale businesses and smaller projects.

Read Our More Blog :